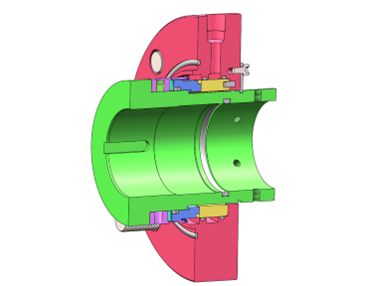

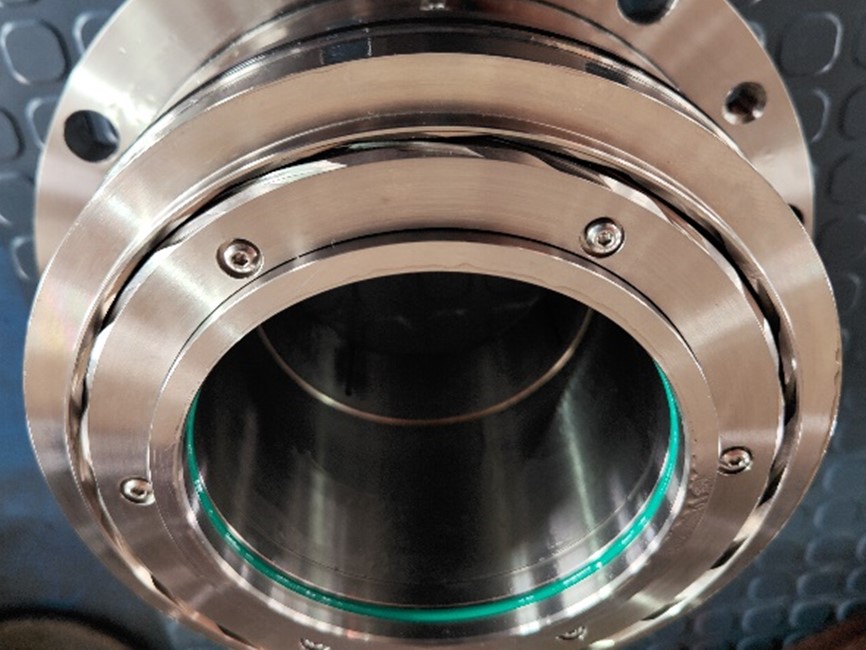

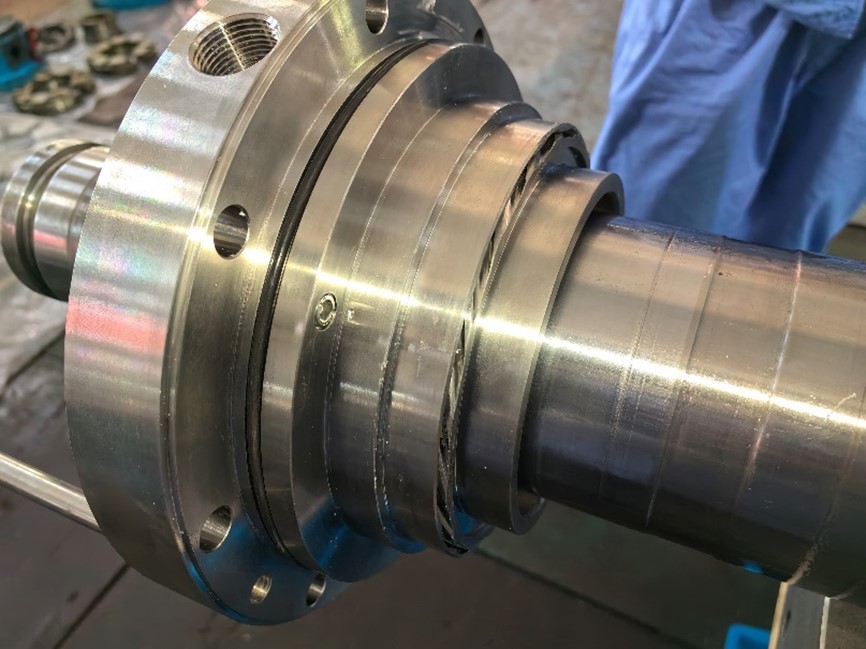

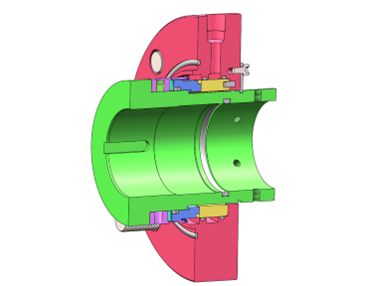

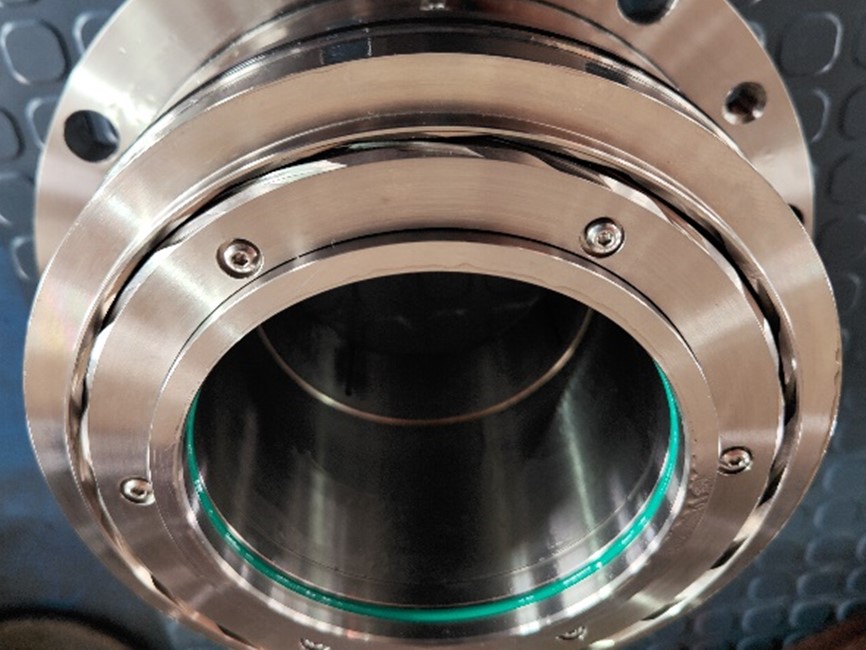

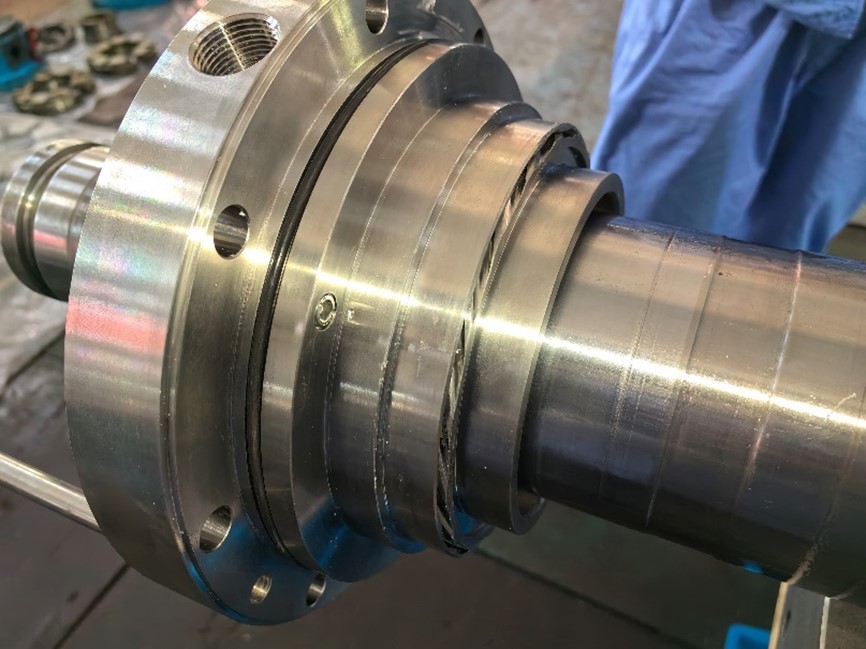

Cartridge Mechanical Seal

Mechanical seal is a key component for controlling fluid leakage in rotating equipment. Its function is to establish a reliable seal between the high-speed rotating shaft and the stationary pump casing/equipment casing, preventing the leakage of working medium (liquid, gas or slurry) or the intrusion of external impurities. Under the harsh working conditions of high temperature, high pressure, high speed, and strong corrosion in thermal power plants, the reliability of mechanical seals is directly related to equipment safety and environmental compliance.

Recommended Products

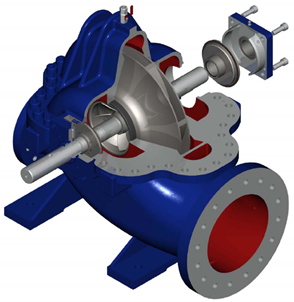

OH Pumps

The OH series process pump is a horizontal, single-stage, end suction centrifugal pump. Its size and performance comply with DIN24256/ISO5199 standards. The OH series process pump is designed with reference to relevant design standards such as ASME/ANSI, B73.1M, and API610, combined with practical applications, and innovatively designed as a high reliability standard process pump.

BB1 Pump

The BB1 series pump is an axial split, single-stage or two-stage, volute shell type, two end supported horizontal centrifugal pump, which can also be designed as a vertical structure. Suitable for conveying various clean or trace particle containing, neutral or corrosive media. The BB1 series pump complies with the American Petroleum Institute API610 10th/API 610 11th design standards.

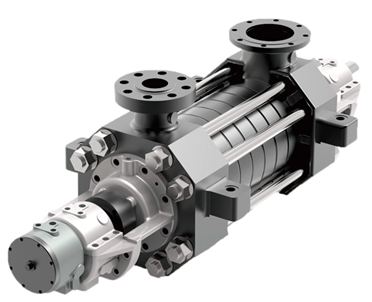

BB4 Pump

The BB4 series pump is a horizontal, single shell, multi-stage, first stage single suction or double suction centrifugal pump, suitable for the power industry, petrochemical processes, and transportation of clean water, high-temperature water, finished oil, liquefied petroleum gas, and other flammable, explosive, or toxic high-temperature and high-pressure liquids that do not contain solid particles. The BB4 series pump complies with the American Petroleum Institute's API 610 10th/API 610 11th design standards.