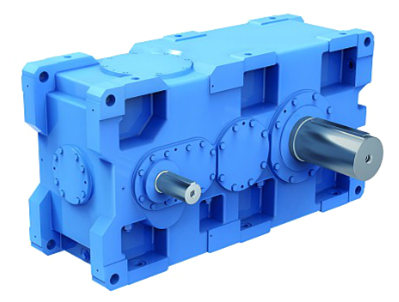

Gearbox

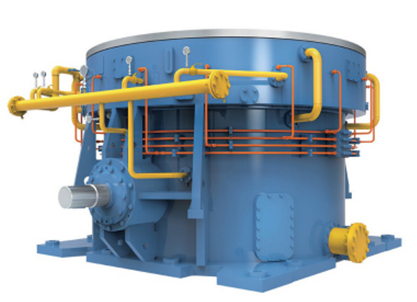

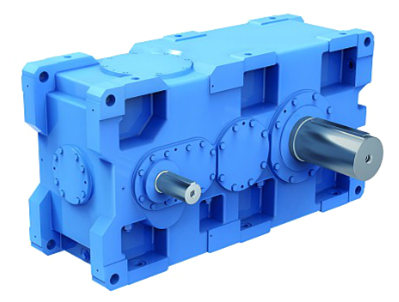

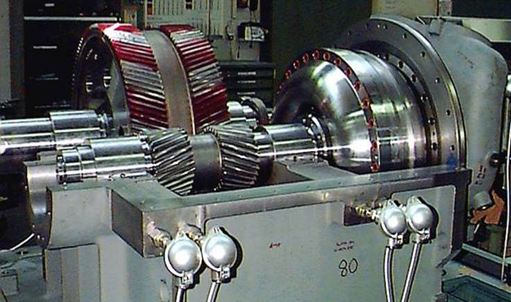

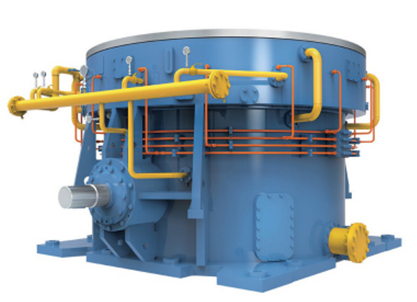

In thermal power plants, gearboxes are crucial power transmission and speed control equipment, mainly concentrated in core auxiliary machines such as coal mills, coal feeders, air preheaters, various fans, water pumps, mixers, coal conveying equipment, dust removal and vibration machines that have strict requirements for low-speed and high torque. The following are the key application positions and roles of reducers in the main systems of thermal power plants.

- Coal mill reducer. Significantly reduce the high speed of the motor (usually 1480rpm or 990rpm) to the required working speed of the grinding disc/bowl (such as~20-30 rpm for medium speed grinding). Most of them are planetary gear reducers or parallel shaft+planetary gear combination reducers.

- Coal feeder reducer. Adjusting the conveying speed of the coal feeder to accurately control the amount of coal entering the coal mill is a key link in boiler load control. Commonly used helical gear reduction motors, worm gear reduction motors, or frequency conversion speed control specialized reducers.

- Drive reducer for air preheater. Reduce the motor speed to the extremely low speed required by the air preheater (usually 0.5-3 rpm). Most of them are worm gear reducers or planetary reducers, requiring low-speed high torque and good self-locking performance.

- Slag removal system reducer. Provide low-speed high torque and drive mechanism to handle high-temperature slag. The working environment is harsh (high temperature, humidity, and high ash content), requiring good sealing, wear resistance, and impact resistance. Commonly used hard tooth surface gear reducers or worm gear reducers.

- Electric feed pump hydraulic coupling (partial design). In the scheme of using a constant speed motor and liquid coupling speed regulation, the hydraulic coupling itself is a continuously variable 'fluid reduction/transmission device'. Match speed, transmit power, and adjust speed.

- Belt conveyor drive reducer. Drive the head drum of the belt conveyor, providing stable torque to drive long-distance, high-capacity belts. Widely use parallel axis helical gear reduction motors or bevel gear helical gear reduction motors.

- Reduction gearbox for desulfurization agitator. Reduce the high speed of the motor to the optimal stirring speed required by the impeller (usually tens to hundreds of rpm). Commonly used parallel axis helical gear reducers or planetary gear reducers.

Recommended Products

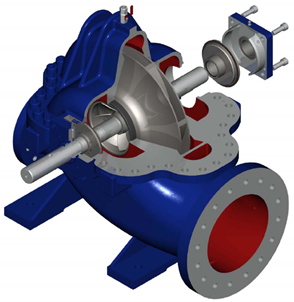

OH Pumps

The OH series process pump is a horizontal, single-stage, end suction centrifugal pump. Its size and performance comply with DIN24256/ISO5199 standards. The OH series process pump is designed with reference to relevant design standards such as ASME/ANSI, B73.1M, and API610, combined with practical applications, and innovatively designed as a high reliability standard process pump.

BB1 Pump

The BB1 series pump is an axial split, single-stage or two-stage, volute shell type, two end supported horizontal centrifugal pump, which can also be designed as a vertical structure. Suitable for conveying various clean or trace particle containing, neutral or corrosive media. The BB1 series pump complies with the American Petroleum Institute API610 10th/API 610 11th design standards.

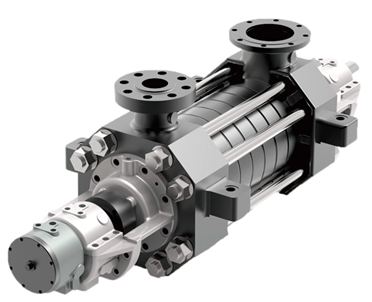

BB4 Pump

The BB4 series pump is a horizontal, single shell, multi-stage, first stage single suction or double suction centrifugal pump, suitable for the power industry, petrochemical processes, and transportation of clean water, high-temperature water, finished oil, liquefied petroleum gas, and other flammable, explosive, or toxic high-temperature and high-pressure liquids that do not contain solid particles. The BB4 series pump complies with the American Petroleum Institute's API 610 10th/API 610 11th design standards.