Company Main Products

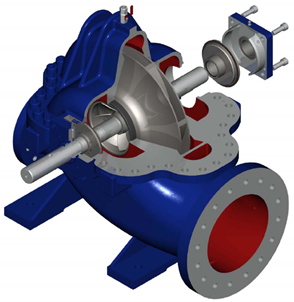

BB1 Pump

The BB1 series pump is an axial split, single-stage or two-stage, volute shell type, two end supported horizontal centrifugal pump, which can also be designed as a vertical structure. Suitable for conveying various clean or trace particle containing, neutral or corrosive media. The BB1 series pump complies with the American Petroleum Institute API610 10th/API 610 11th design standards.

- Standard size: DN150-1600 mm

- Flow: 60-27000 m3/h

- Head: 10-260 m

- Fluid temperature: -10 ℃-110 ℃

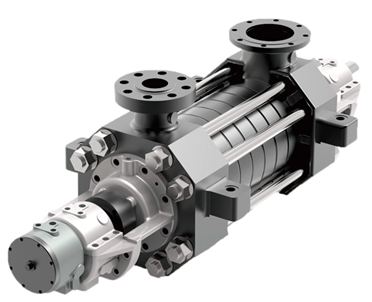

BB4 Pump

The BB4 series pump is a horizontal, single shell, multi-stage, first stage single suction or double suction centrifugal pump, suitable for the power industry, petrochemical processes, and transportation of clean water, high-temperature water, finished oil, liquefied petroleum gas, and other flammable, explosive, or toxic high-temperature and high-pressure liquids that do not contain solid particles. The BB4 series pump complies with the American Petroleum Institute's API 610 10th/API 610 11th design standards.

- Standard size: DN60-450 mm

- Flow: 70-1800 m3/h

- Head: 40-800 m

- Fluid temperature: -40 ℃-180 ℃

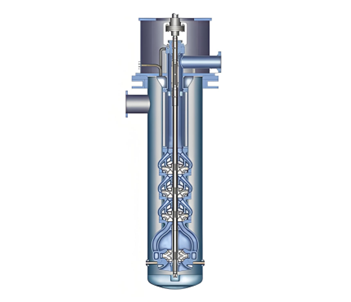

VS Pump

The VS series pump is a vertical single shell, flow channel multi-stage pump, and the first stage impeller can be a single suction or double suction structure, suitable for fields such as thermal power industry, petrochemical industry, sewage treatment, coal chemical industry, etc. The VS series pump complies with the American Petroleum Institute's API 610 10th/API 610 11th design standards

- Standard size: DN120-600 mm

- Flow: 180-3300 m3/h

- Head: 500-160 m

- Fluid temperature: -20 ℃-200 ℃

Cartridge Mechanical Seal

Mechanical seal is a key component for controlling fluid leakage in rotating equipment. Its function is to establish a reliable seal between the high-speed rotating shaft and the stationary pump casing/equipment casing, preventing the leakage of working medium (liquid, gas or slurry) or the intrusion of external impurities. Under the harsh working conditions of high temperature, high pressure, high speed, and strong corrosion in thermal power plants, the reliability of mechanical seals is directly related to equipment safety and environmental compliance.

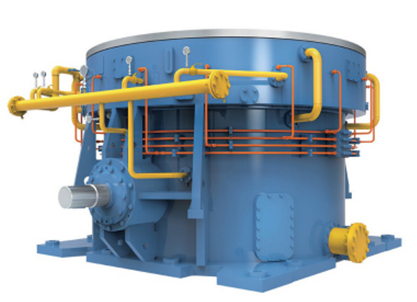

Gearbox

In thermal power plants, gearboxes are crucial power transmission and speed control equipment, mainly concentrated in core auxiliary machines such as coal mills, coal feeders, air preheaters, various fans, water pumps, mixers, coal conveying equipment, dust removal and vibration machines that have strict requirements for low-speed and high torque. The following are the key application positions and roles of reducers in the main systems of thermal power plants.

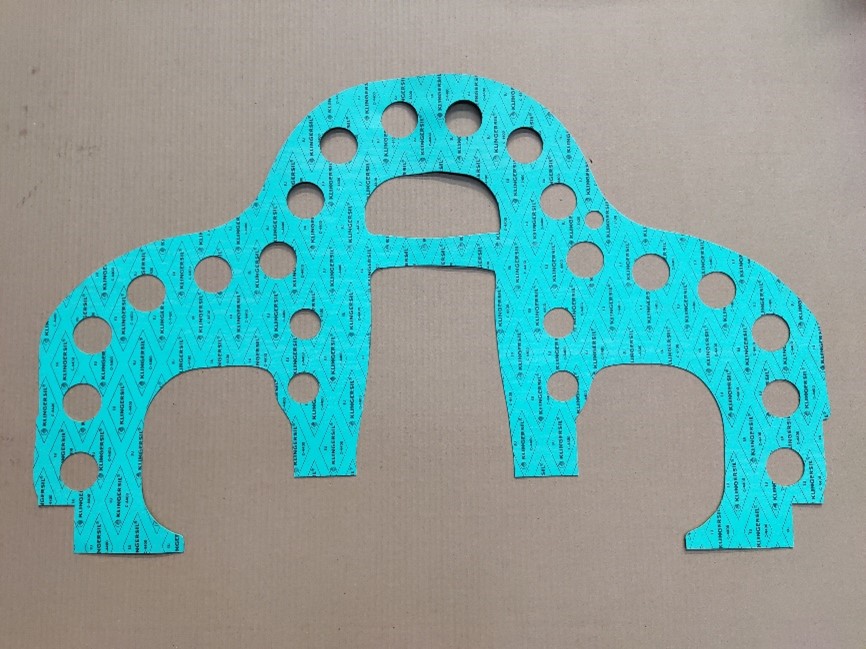

Sealing Element

In thermal power plants, although seals are small, they are the 'micro defense line' that ensures the safe, efficient, and environmentally friendly operation of equipment. They are distributed in harsh environments with high temperature, high pressure, high speed, and strong corrosion. Their core function is to block the leakage path of the medium, prevent energy loss, environmental pollution, or equipment damage.

YCB Series Arc Gear Pump

lt applies to delivering non-corrosive lubricating-oil or equivalent liquid without solid particles and fibres at temperature below 300'C and with the viscosity of 5x10-'. 1.5x10-m’/s(5-1500cSt).lt applies to hydraulic system, too. Reducing the speed, the pump can delivery the liquid that viscosity can be up to 5x10'cSt.

Company Solution

About WEIR Fluid

Beijing Weir Fluid is committed to providing complete fluid equipment and fluid solutions for industrial customers. Our core market areas include coal-fired power plants, gas power plants, oil and gas, petrochemicals, water supply, sewage treatment, steel, etc.

Weil Fluid adheres to a Market-oriented approach and vigorously implements product structure adjustments and product upgrades. In the field of coal-fired power generation, we can provide complete machines, spare parts, and aftermarket services for pump equipment, valves, mixers, grinding rollers, gearboxes, and other equipment. As of 2025, We had served over 100 coal-fired power plants.